In the realm of interior lighting design, the union of single white color low voltage LED strips with aluminum profiles represents a sophisticated and adaptable lighting solution.

This comprehensive guide explores the intricacies of installing single white color low voltage LED strips into aluminum profiles, addressing considerations, installation steps, and common queries to empower enthusiasts and homeowners in their lighting projects.

What is a Single Color Low Voltage LED Strip?

A single color low voltage LED strip is a versatile lighting solution that offers uniform illumination in a single color. These strips typically operate on low voltage DC power, making them energy-efficient and safe for use in residential and commercial settings.

They come in various lengths and brightness levels, offering flexibility in lighting design.

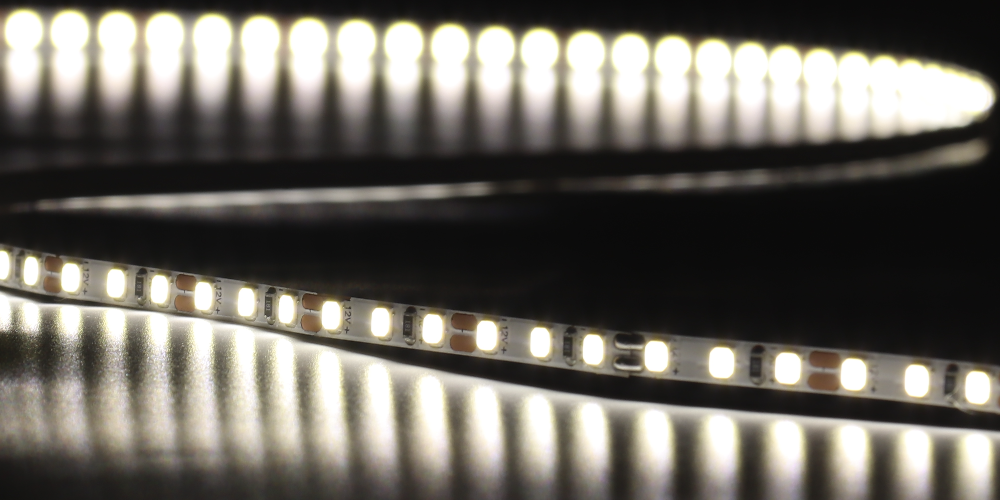

Single color low voltage LED strips consist of individual light-emitting diodes (LEDs) mounted on a flexible circuit board.

These LEDs emit light in a single color, such as warm white, cool white, or daylight white, providing consistent illumination without the need for color mixing. The color temperature of the LEDs determines the tone of the emitted light, ranging from warm and cozy to cool and crisp.

When selecting a single color LED strip, it’s essential to consider factors such as the LED type (e.g., 2835, 5050), which determines the size and brightness of the LEDs, and the density of LEDs per meter, which affects the intensity and uniformity of the light output.

Additionally, the color rendering index (CRI) of the LEDs should be considered, as it indicates how accurately colors are rendered under the light source.

Single color LED strips are commonly used for various applications, including ambient lighting, accent lighting, and task lighting. They can be installed in recessed coves, under cabinets, along staircases, or behind furniture to enhance the visual appeal of indoor spaces.

These LED strips are also popular for decorative purposes, allowing users to create custom lighting effects and atmospheres to suit their preferences.

In summary, single color low voltage LED strips offer a straightforward yet effective lighting solution for a wide range of applications.

With their energy efficiency, versatility, and ease of installation, these LED strips provide an ideal option for enhancing the ambiance and functionality of any indoor environment.

What are Led Aluminum Profiles?

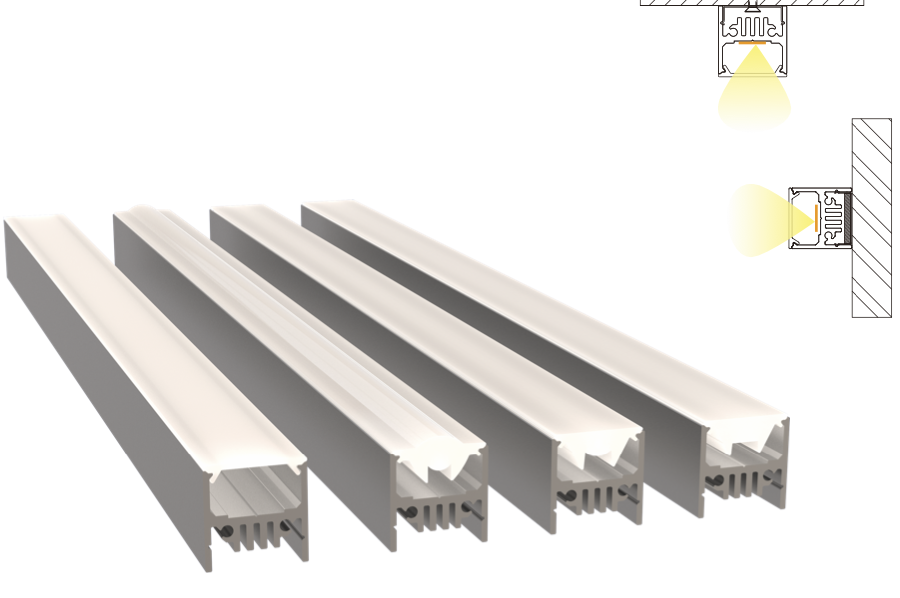

LED aluminum profiles are essential components in LED lighting installations, designed to provide structural support, heat dissipation, and aesthetic enhancement.

These profiles, also known as extrusions or channels, are made from high-quality aluminum and come in various shapes and sizes to accommodate different LED strip types and installation requirements.

LED aluminum profiles serve several crucial functions in LED lighting setups.

Firstly, they act as protective housings for LED strips, shielding them from dust, moisture, and physical damage. This protection extends the lifespan of the LEDs and ensures consistent performance over time.

Additionally, aluminum profiles aid in heat dissipation, helping to dissipate excess heat generated by the LEDs during operation. This thermal management prevents overheating, which can degrade LED performance and reduce lifespan.

Aluminum profiles also contribute to the aesthetics of LED installations, providing a sleek and professional finish. They conceal the LEDs and wiring, creating a clean and polished appearance.

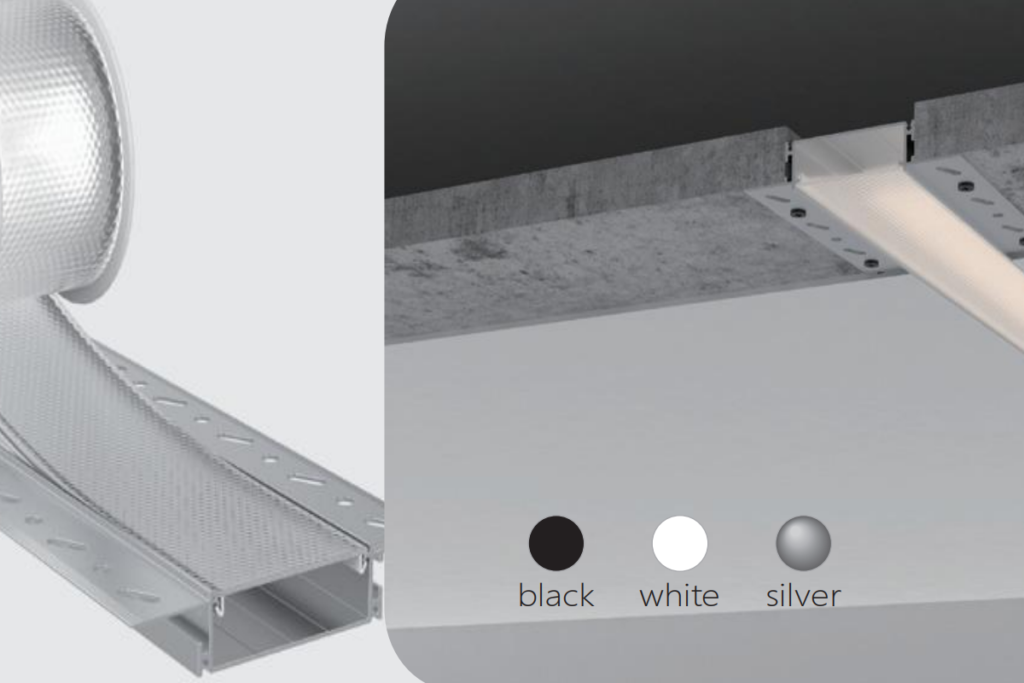

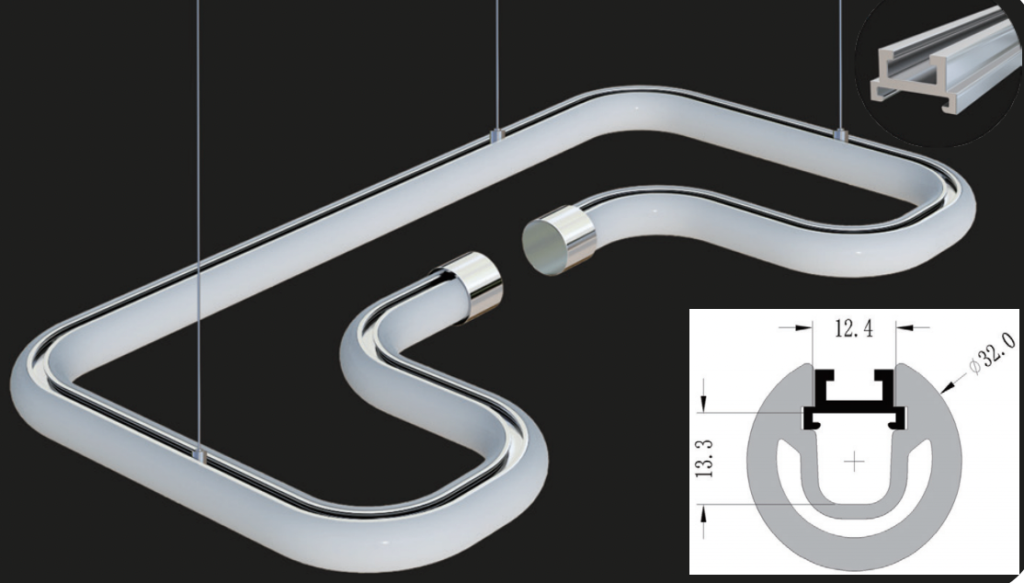

Moreover, aluminum profiles offer versatility in mounting options, allowing for surface mounting, recessed installation, or suspension, depending on the application and design preferences.

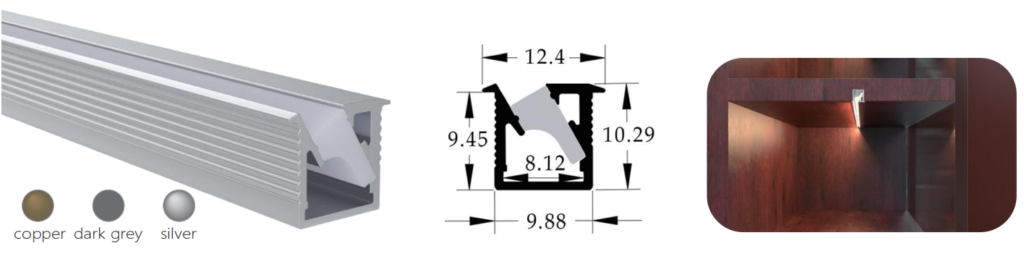

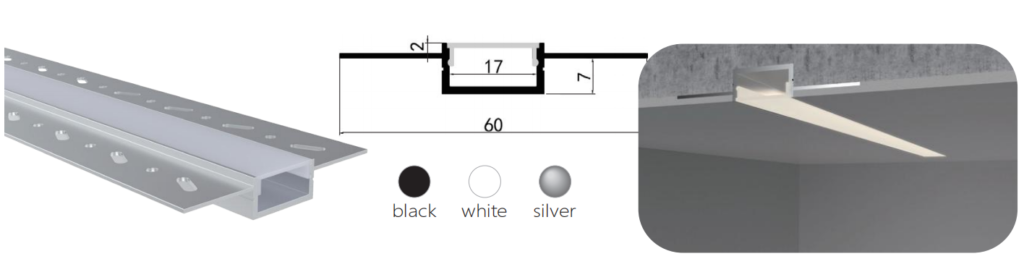

When selecting LED aluminum profiles, it’s essential to consider various factors to ensure compatibility and optimal performance. These factors include the profile shape (e.g., square, rectangular, circular), dimensions (e.g., width, height), and mounting method (e.g., surface mounted, recessed).

Additionally, the profile’s compatibility with specific LED strip types and accessories should be verified to ensure proper fit and functionality.

LED aluminum profiles find application in a wide range of lighting projects, including architectural lighting, interior design, retail displays, and signage.

They are commonly used in residential kitchens, bathrooms, and living spaces to provide accent lighting, task lighting, or ambient illumination. In commercial settings, LED aluminum profiles are utilized in retail stores, restaurants, and offices to create visually appealing lighting effects and enhance the overall ambiance.

In summary, LED aluminum profiles are essential components in LED lighting installations, offering structural support, heat dissipation, and aesthetic enhancement.

With their versatility, durability, and design flexibility, these profiles play a crucial role in creating functional and visually stunning lighting solutions for various indoor and outdoor applications.

How to Install Single White Color Low Voltage LED Strip to LED Aluminum Profile:

Installing single white color low voltage LED strip lights into LED aluminum profiles requires attention to detail and precision to ensure optimal performance and longevity of the lighting system.

Below are detailed steps for a successful installation:

1. Preparation:

- Gather all necessary materials, including the LED strip lights, LED aluminum profiles, mounting accessories, and any required tools such as scissors and adhesive tape.

- Ensure the work area is clean and free from dust or debris to prevent contamination during installation.

2. Measuring and Cutting:

- Measure the length of the LED aluminum profile and LED strip lights required for the installation. Use a tape measure to obtain precise measurements.

- Using a sharp pair of scissors or a cutting tool designed for LED strips, carefully cut the aluminum profile and LED strip lights to the desired lengths. Take care to make clean, straight cuts to ensure proper fitment.

3. Preparing the LED Aluminum Profile:

- Clean the interior of the LED aluminum profile with a soft, dry cloth to remove any dust or debris. Ensure the profile is completely dry before proceeding with installation.

- If necessary, insert any mounting accessories, such as end caps or mounting brackets, into the aluminum profile according to the manufacturer’s instructions.

4. Attaching the LED Strip Lights:

- Peel off the adhesive backing from the LED strip lights, exposing the adhesive side.

- Carefully position the LED strip lights along the interior of the LED aluminum profile, ensuring they are evenly spaced and aligned. Press down firmly to secure the LED strip lights in place.

- Avoid stretching or bending the LED strip lights excessively, as this may damage the adhesive or the LED components.

5. Connecting the LED Strip Lights:

- If using multiple sections of LED strip lights, connect them together using solderless connectors or soldering techniques, following the manufacturer’s instructions.

- Ensure proper polarity alignment when connecting the LED strip lights to avoid damage to the LEDs or the power supply.

6. Securing the LED Aluminum Profile:

- Position the LED aluminum profile in the desired location for installation, ensuring it is aligned correctly.

- Use mounting accessories such as screws, clips, or adhesive tape to secure the LED aluminum profile in place. Ensure the profile is firmly attached to the mounting surface to prevent movement or dislodging.

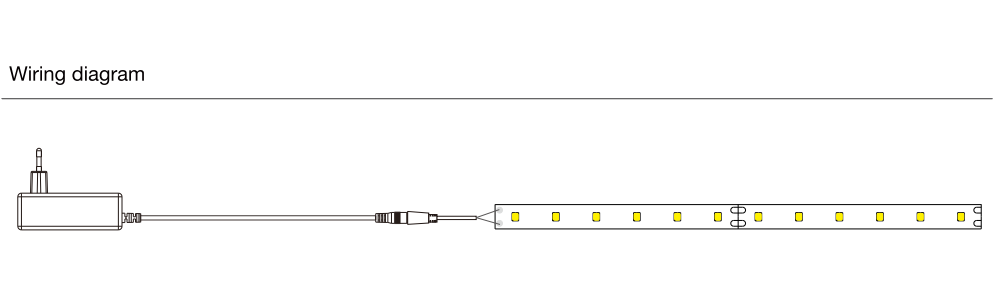

7. Wiring and Power Connection:

- Wire the LED strip lights to the power supply according to the manufacturer’s instructions, ensuring proper polarity alignment.

- Test the LED strip lights to verify functionality and ensure they illuminate evenly and at the desired brightness level.

8. Final Adjustments and Testing:

- Make any final adjustments to the position or alignment of the LED aluminum profile and LED strip lights as needed.

- Test the entire lighting system to ensure all components are functioning correctly and that the installation meets the desired lighting requirements.

9. Safety Considerations:

- Exercise caution when handling LED strip lights and aluminum profiles, as they may have sharp edges or exposed electrical components.

- Ensure all wiring connections are secure and properly insulated to prevent electrical hazards.

10. Maintenance and Care:

- Regularly inspect the LED strip lights and aluminum profiles for signs of damage or wear, such as loose connections or discoloration.

- Clean the LED aluminum profiles and LED strip lights periodically with a soft, dry cloth to remove dust or dirt buildup and maintain optimal performance.

By following these detailed installation steps and paying attention to safety considerations, homeowners and DIY enthusiasts can successfully install single white color low voltage LED strip lights into LED aluminum profiles, creating stunning and functional lighting solutions for various indoor and outdoor applications.

Where to Use Single White Color Low Voltage LED Strip Lights with LED Aluminum Profiles:

Single white color low voltage LED strip lights installed into LED aluminum profiles offer versatile lighting solutions for a wide range of indoor and outdoor applications.

Here are some detailed insights into where these lighting setups can be effectively utilized:

1. Kitchen Lighting:

- Under-Cabinet Lighting: Illuminate countertops and workspace areas with discreetly installed LED aluminum profiles fitted with single white color LED strips. This enhances visibility for food preparation tasks and adds ambiance to the kitchen environment.

- Cabinet and Drawer Lighting: Install LED strips within cabinet and drawer spaces to provide accent lighting and make it easier to locate items stored within. This improves functionality and aesthetics while maximizing storage efficiency.

2. Bathroom Lighting:

- Vanity Lighting: Mount LED aluminum profiles with LED strips along bathroom vanities to supplement overhead lighting and enhance grooming activities. The single white color illumination creates a bright and inviting atmosphere for personal care routines.

- Mirror Lighting: Backlight bathroom mirrors with LED strips installed into aluminum profiles to provide even and glare-free illumination. This enhances visibility and adds a stylish touch to the bathroom decor.

3. Living Room and Bedroom Lighting:

- Ambient Lighting: Conceal LED aluminum profiles with LED strips behind furniture, along walls, or within recessed areas to create ambient lighting effects. This soft, diffuse illumination enhances the overall ambiance of living spaces and promotes relaxation.

- Feature Lighting: Highlight architectural features, artwork, or decorative elements in living rooms and bedrooms with strategically placed LED aluminum profiles and LED strips. This draws attention to focal points and adds visual interest to the room.

4. Office and Workspace Lighting:

- Task Lighting: Install LED aluminum profiles with LED strips above desks, workstations, or shelves to provide task lighting for reading, studying, or working on projects. The bright, focused illumination improves productivity and reduces eye strain.

- Shelving and Storage Lighting: Illuminate office shelves, bookcases, or storage units with LED strips installed into aluminum profiles. This makes it easier to locate and organize items stored within while adding a modern and professional aesthetic.

5. Retail and Display Lighting:

- Product Displays: Enhance the presentation of retail products or merchandise with LED aluminum profiles and LED strips. Use targeted lighting to highlight specific items, create focal points, and attract customer attention.

- Showcases and Exhibits: Illuminate showcases, display cabinets, or exhibition spaces with discreetly installed LED aluminum profiles and LED strips. This accentuates showcased items and contributes to an immersive and engaging customer experience.

6. Outdoor Lighting:

- Patio and Deck Lighting: Install weather-resistant LED aluminum profiles with LED strips along outdoor patios, decks, or pergolas to provide ambient lighting for evening gatherings or relaxation. This extends outdoor living spaces and enhances safety.

- Landscape Lighting: Use LED strips mounted into aluminum profiles to illuminate garden pathways, borders, or architectural features. This enhances the aesthetics of outdoor landscapes and improves visibility in low-light conditions.

By strategically implementing single white color low voltage LED strip lights with LED aluminum profiles in various indoor and outdoor settings, homeowners, designers, and businesses can create customized lighting solutions that enhance functionality, ambiance, and visual appeal across a diverse range of environments.

Factors to Consider When Installing Single White Color Low Voltage LED Strip Lights with LED Aluminum Profiles:

LED Strip Specifications:

- LED Type: Choose between SMD (Surface Mount Device) LED types like 2835 or 5050, where 5050 LEDs offer higher brightness but may require more power.

- Color Temperature: Select the appropriate color temperature for the desired ambiance; warm white (2700K-3500K) creates a cozy atmosphere, while cool white (5000K-6500K) offers brighter, daylight-like illumination.

- LED Density: Decide on LED density per meter based on the desired brightness level and uniformity of light distribution; higher LED density provides greater brightness but may require additional power and heat dissipation.

- Color Rendering Index (CRI): Opt for LEDs with a high CRI (>80) to ensure accurate color representation, particularly important for tasks requiring precise color discrimination.

Aluminum Profile Compatibility:

- Profile Shape and Size: Choose profiles that accommodate the LED strip width and provide sufficient space for heat dissipation; consider factors like depth and width to ensure proper fitment.

- Mounting Method: Determine whether surface-mounted, recessed, or suspended installation is preferred based on the application and aesthetic requirements; ensure the chosen method provides stability and accessibility for maintenance.

Installation Environment:

- Environmental Conditions: Assess the installation environment for factors such as humidity, temperature fluctuations, and exposure to dust or moisture; select LED strips and profiles with appropriate IP ratings for indoor or outdoor use.

- Ventilation: Ensure adequate airflow around the LED strips within the profiles to prevent overheating, which can degrade performance and reduce lifespan; consider ventilation options like vents or heat sinks for improved thermal management.

Power Supply and Wiring:

- Voltage Compatibility: Match the LED strip voltage requirements with the power supply output to prevent damage and ensure safe operation; consider voltage drop over long distances and use appropriate wire gauge to minimize power loss.

- Wiring Layout: Plan the wiring layout to minimize voltage drop and ensure even illumination along the length of the LED strips; use solderless connectors or soldering techniques for secure and reliable connections.

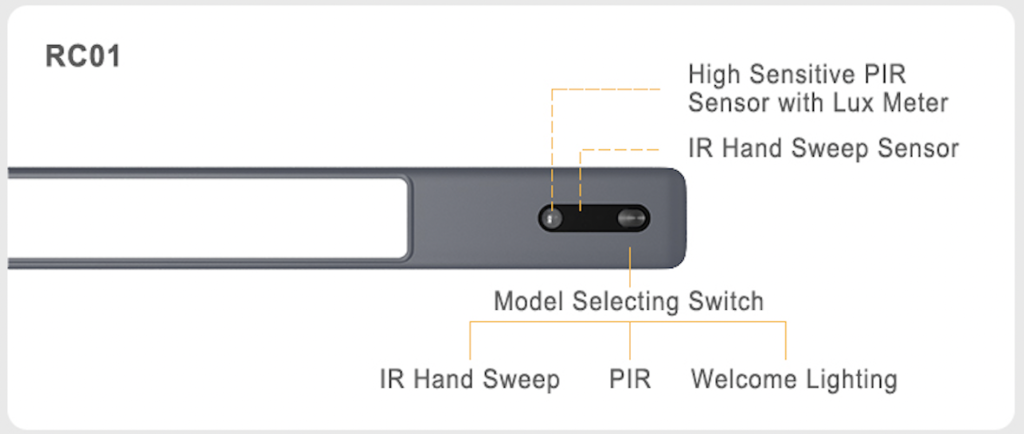

Sensor Switch and Dimming Compatibility:

- Sensor Integration: If incorporating sensor switches or dimmers, verify compatibility with the LED strips and profiles; consider factors like sensor range, sensitivity, and response time for seamless integration and reliable operation.

- Dimming Functionality: Choose dimmable LED strips and compatible dimming controllers for adjustable brightness levels and dynamic lighting effects; ensure compatibility with the selected LED driver and control system for optimal performance.

Aesthetic and Design Considerations:

- Profile Finish: Select profile finishes (e.g., clear anodized, frosted diffuser) that complement the surrounding decor and architectural elements; consider factors like light diffusion and glare reduction for enhanced visual comfort.

- Visibility: Determine whether the LED strips and profiles will be visible or concealed within architectural elements or fixtures; choose profile designs and mounting methods that align with the desired aesthetic outcome.

Safety Precautions:

- Electrical Safety: Adhere to electrical codes and regulations when installing LED strips and profiles; ensure proper insulation, grounding, and protection against electrical hazards to minimize the risk of shock or fire.

- Heat Management: Implement heat sinks, thermal pads, or other thermal management solutions to dissipate heat generated by the LED strips effectively; monitor operating temperatures to prevent overheating and ensure long-term reliability.

By meticulously considering these factors and addressing them during the planning and installation phases, individuals can achieve a successful integration of single white color low voltage LED strip lights with LED aluminum profiles, resulting in a tailored lighting solution that meets the functional, aesthetic, and safety requirements of the application.

Frequently Asked Questions (FAQs) About Installing Single White Color Low Voltage LED Strip Lights with LED Aluminum Profiles:

- Can I cut the LED strip lights to fit my installation size?

- Yes, most LED strip lights are designed to be cut at designated cut points, typically marked at intervals along the strip. Ensure you cut along these points to maintain proper functionality and avoid damaging the circuitry.

- Do I need to use aluminum profiles for LED strip installations?

- While not mandatory, aluminum profiles offer several benefits, including heat dissipation, protection for the LEDs, and a sleek aesthetic. They also make installation and maintenance easier by providing a secure housing for the LED strips.

- Are single white color LED strips suitable for outdoor use?

- Single white color LED strips can be used outdoors if they are rated for outdoor use (usually indicated by an IP rating). Ensure that both the LED strips and aluminum profiles have appropriate weatherproofing to withstand exposure to the elements.

- What adhesive should I use to secure LED strips in aluminum profiles?

- Double-sided adhesive tape with strong bonding properties is commonly used to secure LED strips in aluminum profiles. Make sure the adhesive is suitable for the intended application and can withstand the environmental conditions.

- Can multiple LED strips be connected to a single power source?

- Yes, multiple LED strips can be connected to a single power source as long as the power supply’s wattage and voltage output are sufficient to accommodate the total power consumption of all connected LED strips.

- How can I achieve uniform illumination along the length of the LED strip?

- To achieve uniform illumination, ensure proper spacing and alignment of the LED strip within the aluminum profile. Additionally, consider using LED strips with higher LED density or diffusers to evenly distribute light output.

- Are waterproof LED strips and aluminum profiles available?

- Yes, waterproof LED strips and aluminum profiles are available for use in environments where moisture or water exposure is a concern. These components are rated with an IP (Ingress Protection) rating indicating their level of water resistance.

- Can LED strips be installed on curved surfaces?

- Yes, flexible LED strips can be bent and installed on curved surfaces with appropriate bending techniques. Ensure that the LED strips are flexible enough to bend without damaging the LEDs or circuitry.

- What safety precautions should I take during installation?

- When working with electricity, always turn off the power source before making any connections. Follow safety guidelines provided by manufacturers and use appropriate personal protective equipment (PPE) when handling tools or working at heights.

- How do I troubleshoot common issues with LED strip installations?

- Common issues include flickering lights, uneven brightness, and poor connectivity. Troubleshoot by checking for loose connections, ensuring proper polarity, and inspecting for damaged components. Consult manufacturer guidelines or seek professional assistance if necessary.

By addressing these frequently asked questions with detailed explanations, individuals can gain a better understanding of the considerations and procedures involved in installing single white color low voltage LED strip lights with LED aluminum profiles, enabling them to undertake successful lighting projects with confidence.

Conclusion:

In conclusion, the integration of single white color low voltage LED strips into aluminum profiles offers a seamless and versatile lighting solution for various indoor applications.

By adhering to proper installation procedures and considering important factors such as LED strip specifications, aluminum profile compatibility, and safety measures, homeowners and enthusiasts can create customized lighting installations that enhance both functionality and aesthetics within their living spaces.

With the flexibility of LED technology and the durability of aluminum profiles, the possibilities for creative lighting designs are endless, allowing individuals to personalize their environments with efficient and stylish lighting solutions.