Choosing a reliable low voltage 3528 LED strip light manufacturer in China requires careful consideration of several factors to ensure quality, reliability, and compliance with safety standards.

Here’s a step-by-step guide:

Thoroughly Research and Identify Potential Manufacturers:

Begin your search for a reliable low voltage 3528 LED strip light manufacturer in China by conducting comprehensive research.

Utilize various resources such as online directories, industry-specific forums, trade magazines, and professional networks to compile a list of potential manufacturers.

- Online Directories:

Explore popular online platforms like Alibaba, Made-in-China, and Global Sources to find a wide range of LED strip light manufacturers in China.

These directories offer detailed profiles, product listings, and reviews, making it easier to assess the credibility and capabilities of different suppliers. - Trade Shows and Exhibitions:

Attend trade shows, exhibitions, and industry events related to lighting, electronics, and manufacturing.

These events provide an excellent opportunity to connect with manufacturers face-to-face, examine product samples, and establish direct communication channels. - Industry Associations and Forums:

Join industry-specific forums, discussion groups, and professional associations related to LED lighting and electronics manufacturing.

Engage with other members, seek recommendations, and gather insights into reputable manufacturers based on their collective experiences and expertise. - Supplier Verification Services:

Consider utilizing supplier verification services or third-party inspection agencies to validate the credentials and reliability of potential manufacturers.

These services conduct background checks, factory audits, and quality assessments to ensure compliance with industry standards and regulations. - Local Chambers of Commerce:

Contact local chambers of commerce, trade promotion agencies, or business development organizations in China for assistance in identifying reputable manufacturers.

They can provide valuable insights, referrals, and support in navigating the complexities of sourcing from overseas suppliers.

Through thorough research and due diligence, you can compile a list of potential LED strip light manufacturers in China that align with your requirements in terms of product quality, reliability, and business compatibility.

Check Certifications, Compliance, and Manufacturing Standards

When evaluating potential low voltage 3528 LED strip light manufacturers in China, it’s essential to verify their adherence to industry certifications, compliance with regulatory standards, and commitment to manufacturing excellence.

- Certifications and Regulatory Compliance:

Prioritize manufacturers who possess relevant certifications such as CE (Conformité Européenne), RoHS (Restriction of Hazardous Substances), UL (Underwriters Laboratories), and FCC (Federal Communications Commission).

These certifications indicate that the LED strip lights meet stringent quality, safety, and environmental standards required for international markets. - ISO Standards:

Inquire whether the manufacturer adheres to ISO (International Organization for Standardization) standards, particularly ISO 9001 for quality management systems and ISO 14001 for environmental management systems.

Compliance with these standards demonstrates the manufacturer’s dedication to maintaining consistent quality, efficient processes, and environmental sustainability throughout their operations. - Product Testing and Compliance Documentation:

Request detailed information on the manufacturer’s product testing procedures, including reliability testing, performance testing, and safety testing.

Obtain copies of compliance documentation, test reports, and certificates to validate the LED strip lights’ compliance with applicable standards and regulations. - Material Sourcing and Traceability:

Investigate the manufacturer’s practices regarding material sourcing, procurement, and supply chain management.

Ensure that they source high-quality components and materials from reputable suppliers and maintain traceability throughout the production process to guarantee product integrity and reliability. - Environmental and Ethical Considerations:

Assess the manufacturer’s commitment to environmental sustainability, ethical labor practices, and corporate social responsibility (CSR).

Inquire about their efforts to minimize environmental impact, reduce waste, and ensure fair treatment of workers in compliance with international labor standards.

By thoroughly examining the manufacturer’s certifications, compliance documentation, and commitment to manufacturing standards, you can ensure that they uphold the highest levels of quality, safety, and ethical conduct in producing low voltage 3528 LED strip lights.

Assess Quality Assurance Processes and Procedures

It’s crucial to evaluate the quality assurance processes and procedures implemented by the low voltage 3528 LED strip light manufacturer in China to ensure consistent product quality, reliability, and performance.

- Quality Control Measures:

Inquire about the manufacturer’s quality control measures, including inspection protocols, testing procedures, and quality assurance checkpoints throughout the production process.

A reputable manufacturer should have robust quality control systems in place to detect and address any deviations or defects promptly. - Incoming Material Inspection:

Ask about the manufacturer’s procedures for inspecting and verifying the quality of incoming raw materials and components used in the production of LED strip lights.

This ensures that only materials meeting specified standards are utilized, minimizing the risk of manufacturing defects and ensuring product consistency. - In-Process Inspection and Testing:

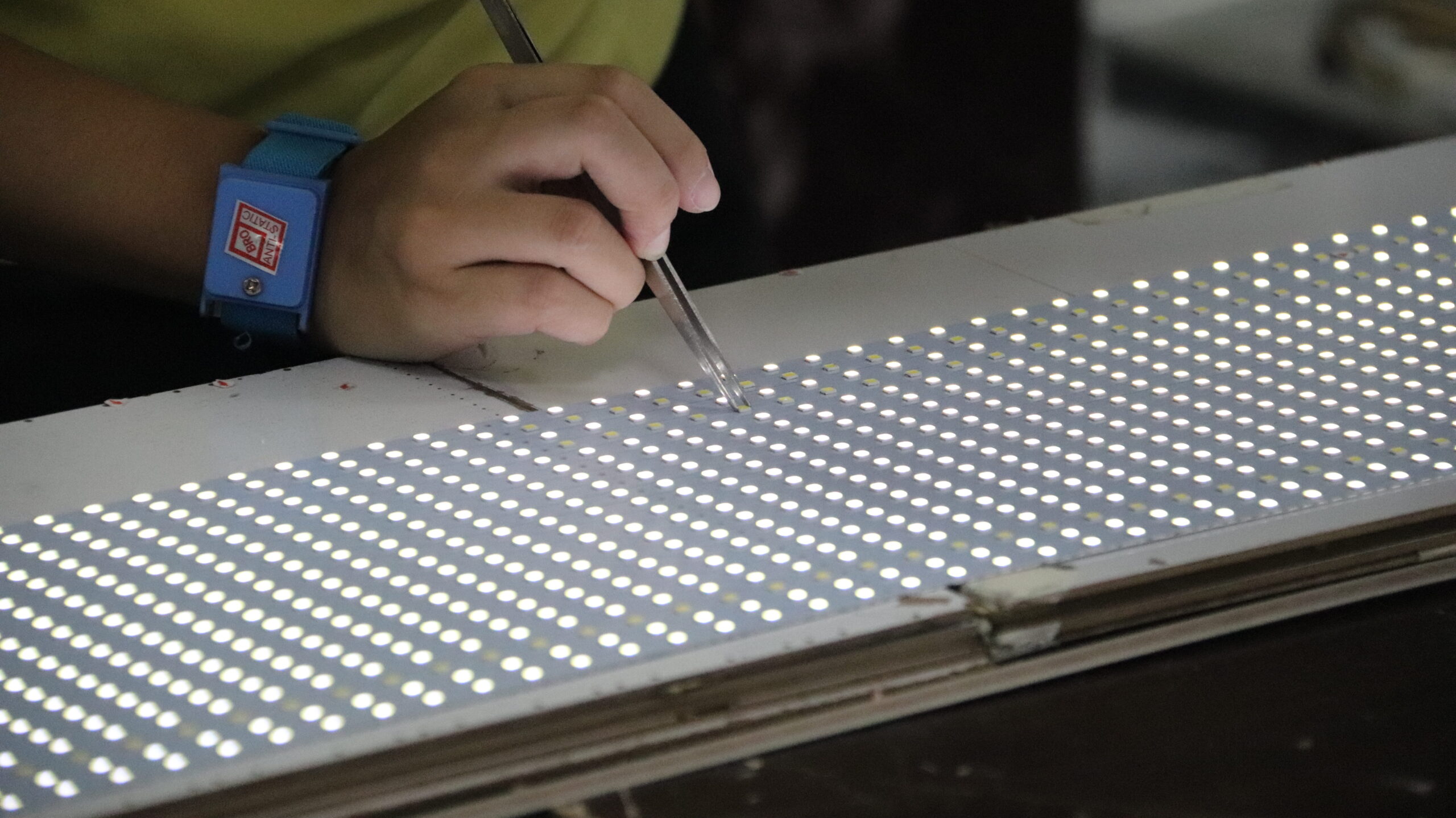

Learn about the in-process inspection and testing procedures employed during manufacturing to monitor product quality and identify any issues early in the production cycle.

This may include visual inspections, functional testing, and performance validation against specifications and industry standards. - Final Product Inspection:

Enquire about the final product inspection process conducted before packaging and shipment.

The manufacturer should perform comprehensive inspections to assess key parameters such as brightness, color consistency, electrical performance, and physical integrity to ensure that finished LED strip lights meet quality standards and customer expectations. - Defect Resolution and Continuous Improvement:

Discuss how the manufacturer addresses quality issues and implements corrective actions to resolve defects and prevent recurrence.

A proactive approach to defect resolution and continuous improvement demonstrates a commitment to delivering high-quality products and customer satisfaction. - Quality Management System Certification:

Verify whether the manufacturer has obtained certification for a recognized quality management system, such as ISO 9001. Certification indicates adherence to internationally recognized quality management standards and a commitment to maintaining rigorous quality assurance practices.

By assessing the quality assurance processes and procedures of the LED strip light manufacturer, you can gain confidence in their ability to consistently deliver products that meet your quality standards and specifications, fostering trust and long-term collaboration.

Request Product Samples for Evaluation

Before committing to a partnership with a low voltage 3528 LED strip light manufacturer in China, it’s essential to request product samples to assess the quality, performance, and suitability of their LED strip lights.

Conducting a thorough evaluation of samples helps ensure that the products meet your specific requirements and standards.

- Sample Variety:

Request samples of different types and configurations of 3528 LED strip lights offered by the manufacturer, including variations in color temperature, brightness levels, and optional features such as waterproofing or dimming capabilities.

This allows you to evaluate the manufacturer’s product range and choose the most suitable options for your applications. - Quality Assessment:

Inspect the quality of the LED strip lights by closely examining the construction, materials, and workmanship.

Pay attention to details such as soldering joints, LED chip alignment, and overall build quality to identify any signs of poor craftsmanship or potential durability issues. - Brightness and Color Consistency:

Evaluate the brightness and color consistency of the LED strip lights by illuminating the samples and comparing them under various lighting conditions.

Ensure that the brightness levels meet your expectations and that the color temperature remains consistent across the entire length of the strip. - Durability and Reliability:

Assess the durability and reliability of the LED strip lights by subjecting the samples to stress tests, including bending, flexing, and exposure to environmental factors such as temperature fluctuations and humidity.

Verify that the LED strip lights can withstand typical usage conditions without degradation or failure. - Functionality Testing:

Test the functionality of the LED strip lights by connecting them to a power source and verifying that they operate as intended.

Check for issues such as flickering, uneven illumination, or compatibility with dimming controls if applicable. Ensure that the LED strip lights meet your performance requirements and specifications. - Comparative Analysis:

Compare the samples from different manufacturers to benchmark quality, performance, and value. Consider factors such as price, warranty terms, and additional services offered by each manufacturer to make an informed decision.

By thoroughly evaluating product samples from the LED strip light manufacturer, you can verify the quality, performance, and suitability of their products for your specific needs, ultimately ensuring a successful partnership and satisfactory outcomes.

Explore Customization Options and Technical Expertise

When selecting a low voltage 3528 LED strip light manufacturer in China, it’s important to inquire about their ability to customize products to meet your specific requirements and technical specifications.

A manufacturer with expertise in customization can provide tailored solutions that align with your unique needs and preferences.

- Custom Design Capabilities:

Discuss with the manufacturer their capabilities for customizing LED strip lights according to your desired specifications, such as length, color temperature, brightness levels, and special features like waterproofing or color-changing options.

Inquire about their design expertise and willingness to accommodate custom requests. - Technical Consultation and Support:

Seek technical consultation and support from the manufacturer to optimize the design and performance of LED strip lights for your applications.

A knowledgeable manufacturer can provide valuable insights, recommendations, and guidance on factors such as LED chip selection, circuit design, and thermal management. - Prototype Development: Evaluate the manufacturer’s ability to develop prototypes or samples based on your custom requirements for testing and validation.

A collaborative approach to prototype development allows for iterative refinement and ensures that the final product meets your expectations and performance criteria. - Flexibility in Production Processes:

Assess the manufacturer’s flexibility in adapting production processes to accommodate custom orders and varying production volumes.

A flexible manufacturer can adjust production schedules, tooling, and assembly lines to meet your specific project timelines and volume requirements. - Quality Assurance for Customized Products:

Inquire about the manufacturer’s quality assurance processes for customized products to ensure consistency, reliability, and compliance with specifications.

Verify that customized LED strip lights undergo rigorous testing and inspection to maintain high standards of quality and performance. - Cost and Lead Time Considerations:

Discuss pricing, lead times, and minimum order quantities (MOQs) for custom orders with the manufacturer to align expectations and budget constraints.

Balance cost considerations with the desired level of customization and quality to achieve the best value proposition for your project.

By exploring customization options and technical expertise offered by the LED strip light manufacturer, you can collaborate effectively to develop tailored solutions that meet your specific requirements and deliver optimal performance for your applications.

Evaluate Communication Channels and Support Services

Effective communication and responsive support are essential factors to consider when selecting a low voltage 3528 LED strip light manufacturer in China.

Clear and efficient communication channels, coupled with reliable customer support services, are crucial for ensuring a smooth and successful collaboration.

- Communication Channels:

Assess the manufacturer’s communication channels, including email, phone, messaging apps, and video conferencing platforms.

Evaluate their responsiveness and availability to address inquiries, provide updates, and discuss project requirements in a timely manner. - Language Proficiency:

Consider the language proficiency of the manufacturer’s team members, especially if English is not their native language.

Effective communication relies on mutual understanding and clarity, so ensure that language barriers are minimized through proficient communication skills or translation services if necessary. - Dedicated Account Manager or Sales Representative:

Inquire whether the manufacturer assigns a dedicated account manager or sales representative to serve as your primary point of contact.

A dedicated contact person can streamline communication, facilitate coordination, and address any issues or concerns promptly throughout the duration of the partnership. - Technical Support and Expertise:

Evaluate the manufacturer’s technical support capabilities and expertise in providing assistance with product selection, troubleshooting, and application-specific guidance.

Access to knowledgeable technical support professionals can help resolve technical challenges and optimize the performance of LED strip lights for your applications. - Pre-Sales Consultation and Customization Support:

Seek pre-sales consultation and customization support from the manufacturer to discuss project requirements, explore product options, and tailor solutions to meet your specific needs.

A manufacturer that offers comprehensive pre-sales support demonstrates a commitment to understanding your requirements and providing tailored solutions. - After-Sales Service and Warranty:

Inquire about the manufacturer’s after-sales service policies, including warranty coverage, returns, and repairs. Verify the terms and conditions of the warranty, including duration, coverage, and any limitations or exclusions.

A manufacturer that stands behind their products with a robust warranty and responsive after-sales support enhances confidence and trust in their reliability. - Feedback and Issue Resolution:

Discuss the manufacturer’s approach to collecting feedback and resolving issues or concerns that may arise during the collaboration.

Transparent communication, proactive problem-solving, and a commitment to customer satisfaction are key indicators of a manufacturer’s dedication to fostering positive relationships and addressing customer needs effectively.

By evaluating communication channels and support services provided by the LED strip light manufacturer, you can ensure effective collaboration, timely resolution of issues, and a positive overall experience throughout the partnership.

Consider Pricing, Payment Terms, and Value Proposition

While evaluating low voltage 3528 LED strip light manufacturers in China, it’s important to consider not only the pricing offered but also the overall value proposition, including payment terms, product quality, and additional services provided.

- Competitive Pricing:

Compare pricing quotes from multiple manufacturers to assess competitiveness within the market. However, prioritize value over the lowest price, as exceptionally low prices may indicate compromises in quality or service. - Transparent Pricing Structure:

Seek transparency in the manufacturer’s pricing structure, including itemized costs for materials, labor, overheads, and profit margins.

Clear pricing breakdowns enable you to understand the cost components and make informed decisions. - Volume Discounts and MOQs:

Inquire about volume discounts and minimum order quantities (MOQs) offered by the manufacturer. Bulk orders often qualify for discounted pricing, but ensure that MOQs align with your project requirements and budget constraints. - Payment Terms and Conditions:

Clarify payment terms, including deposit requirements, milestone payments, and final payment terms. Negotiate favorable payment terms that provide flexibility and mitigate financial risks, such as payment upon delivery or payment through secure escrow services. - Value-added Services:

Evaluate the value-added services provided by the manufacturer, such as customization support, technical assistance, and logistics coordination.

Manufacturers offering comprehensive services beyond product manufacturing may deliver greater value and support throughout the partnership. - Quality-to-Price Ratio:

Assess the quality-to-price ratio of LED strip lights offered by the manufacturer.

Consider factors such as product quality, performance, durability, and warranty coverage when evaluating the overall value proposition. - Total Cost of Ownership (TCO):

Consider the total cost of ownership over the product lifecycle, including initial purchase price, maintenance costs, energy efficiency, and potential savings or returns on investment.

Opt for LED strip lights that offer a favorable TCO by balancing upfront costs with long-term benefits. - Negotiation and Customization:

Engage in negotiations with the manufacturer to explore opportunities for cost savings, value-added services, or customizations tailored to your specific requirements.

Negotiation can help optimize pricing and terms to align with your budget and project objectives.

By considering pricing, payment terms, and the overall value proposition offered by the LED strip light manufacturer, you can make informed decisions that balance cost considerations with product quality, service levels, and long-term benefits, ultimately maximizing the value of your investment.

Assess Supplier Reputation, Reliability, and Track Record

When selecting a low voltage 3528 LED strip light manufacturer in China, it’s essential to assess the supplier’s reputation, reliability, and track record to ensure a trustworthy and successful partnership.

- Industry Reputation and Reviews:

Research the manufacturer’s reputation within the LED lighting industry by seeking reviews, testimonials, and feedback from previous customers.

Online platforms, forums, and industry networks can provide valuable insights into the manufacturer’s performance, reliability, and customer satisfaction. - References and Case Studies:

Request references or case studies from the manufacturer to validate their track record and success stories with previous clients.

Contacting references directly allows you to gain firsthand perspectives on the manufacturer’s capabilities, communication, and service quality. - Years of Experience and Industry Presence:

Consider the manufacturer’s years of experience and longevity in the industry as indicators of stability and reliability.

Established manufacturers with a proven track record of delivering quality products and services are more likely to provide consistent performance and support. - Certifications and Awards:

Look for manufacturers that have earned certifications, awards, or recognitions for excellence in manufacturing, quality management, or customer satisfaction.

Certifications such as ISO 9001 or industry awards highlight the manufacturer’s commitment to quality and continuous improvement. - Supplier Audits and Assessments:

Conduct supplier audits or assessments to evaluate the manufacturer’s facilities, processes, and capabilities firsthand.

A site visit allows you to inspect production facilities, quality control measures, and overall operational efficiency, providing valuable insights into the manufacturer’s reliability and suitability. - Supply Chain Transparency and Ethics:

- Inquire about the manufacturer’s supply chain transparency, ethical practices, and commitment to social and environmental responsibility.

Verify compliance with labor standards, environmental regulations, and ethical sourcing practices to ensure alignment with your values and corporate responsibility objectives. - Financial Stability and Capacity:

Assess the manufacturer’s financial stability and production capacity to fulfill your requirements effectively.

A financially stable manufacturer with adequate production capabilities can accommodate fluctuating demand, meet delivery deadlines, and mitigate supply chain risks. - Communication and Responsiveness:

Evaluate the manufacturer’s communication and responsiveness throughout the sourcing process, from initial inquiries to ongoing support.

Prompt responses, transparent communication, and proactive engagement demonstrate reliability and commitment to customer satisfaction.

By thoroughly assessing the supplier’s reputation, reliability, and track record, you can mitigate risks, build trust, and establish a mutually beneficial partnership with a low voltage 3528 LED strip light manufacturer in China.

Ensure Intellectual Property Protection and Legal Compliance

When engaging with a low voltage 3528 LED strip light manufacturer in China, it’s crucial to prioritize intellectual property (IP) protection and ensure compliance with relevant legal regulations to safeguard your proprietary designs, innovations, and business interests.

- Non-Disclosure Agreements (NDAs) and Confidentiality:

Require the manufacturer to sign non-disclosure agreements (NDAs) or confidentiality agreements to protect your confidential information, including product designs, specifications, and proprietary technologies.

NDAs establish legal safeguards against unauthorized disclosure or use of sensitive information. - Intellectual Property Rights (IPR) Protection:

Verify the manufacturer’s commitment to respecting intellectual property rights and preventing infringement of third-party patents, trademarks, or copyrights.

Ensure that the manufacturer has internal policies and procedures in place to uphold IPR protection and compliance with applicable laws and regulations. - IPR Due Diligence and Audits:

Conduct due diligence and audits to assess the manufacturer’s adherence to intellectual property laws and regulations.

Verify that the manufacturer has implemented measures to prevent counterfeiting, piracy, or unauthorized replication of proprietary designs or trademarks. - Customs Compliance and Import Regulations:

Familiarize yourself with customs compliance requirements and import regulations governing LED lighting products in your target markets.

Ensure that the manufacturer adheres to relevant customs regulations, trade agreements, and product labeling requirements to facilitate smooth importation and compliance with local laws. - Legal Documentation and Contracts:

Draft comprehensive legal contracts and agreements, including manufacturing agreements, purchase orders, and terms of service, to formalize the business relationship with the manufacturer.

Clearly outline rights, obligations, responsibilities, and dispute resolution mechanisms to mitigate legal risks and ensure contractual clarity. - Enforcement Mechanisms and Remedies:

Establish enforcement mechanisms and remedies in case of contractual breaches, intellectual property infringements, or disputes with the manufacturer.

Define dispute resolution procedures, jurisdictional clauses, and remedies for non-compliance to protect your legal interests and facilitate resolution of conflicts. - Continuous Monitoring and Compliance Management:

Implement mechanisms for continuous monitoring and compliance management throughout the duration of the partnership with the manufacturer.

Regular audits, inspections, and performance evaluations help ensure ongoing adherence to legal and contractual requirements and mitigate potential risks. - Legal Counsel and Expert Advice:

Seek guidance from legal counsel or intellectual property experts with experience in international manufacturing and trade laws.

Legal professionals can provide valuable advice, assistance with contract negotiations, and strategic guidance to safeguard your intellectual property and mitigate legal risks effectively.

By prioritizing intellectual property protection and legal compliance in your partnership with the LED strip light manufacturer, you can mitigate risks, safeguard proprietary assets, and ensure a secure and legally compliant business relationship.

Visit the Manufacturer’s Factory

Visiting the factory of the low voltage 3528 LED strip light manufacturer in China is a crucial step in assessing their capabilities, quality standards, and production processes.

A firsthand inspection allows you to gather valuable insights and make informed decisions about the suitability of the manufacturer for your needs.

- Schedule a Site Visit:

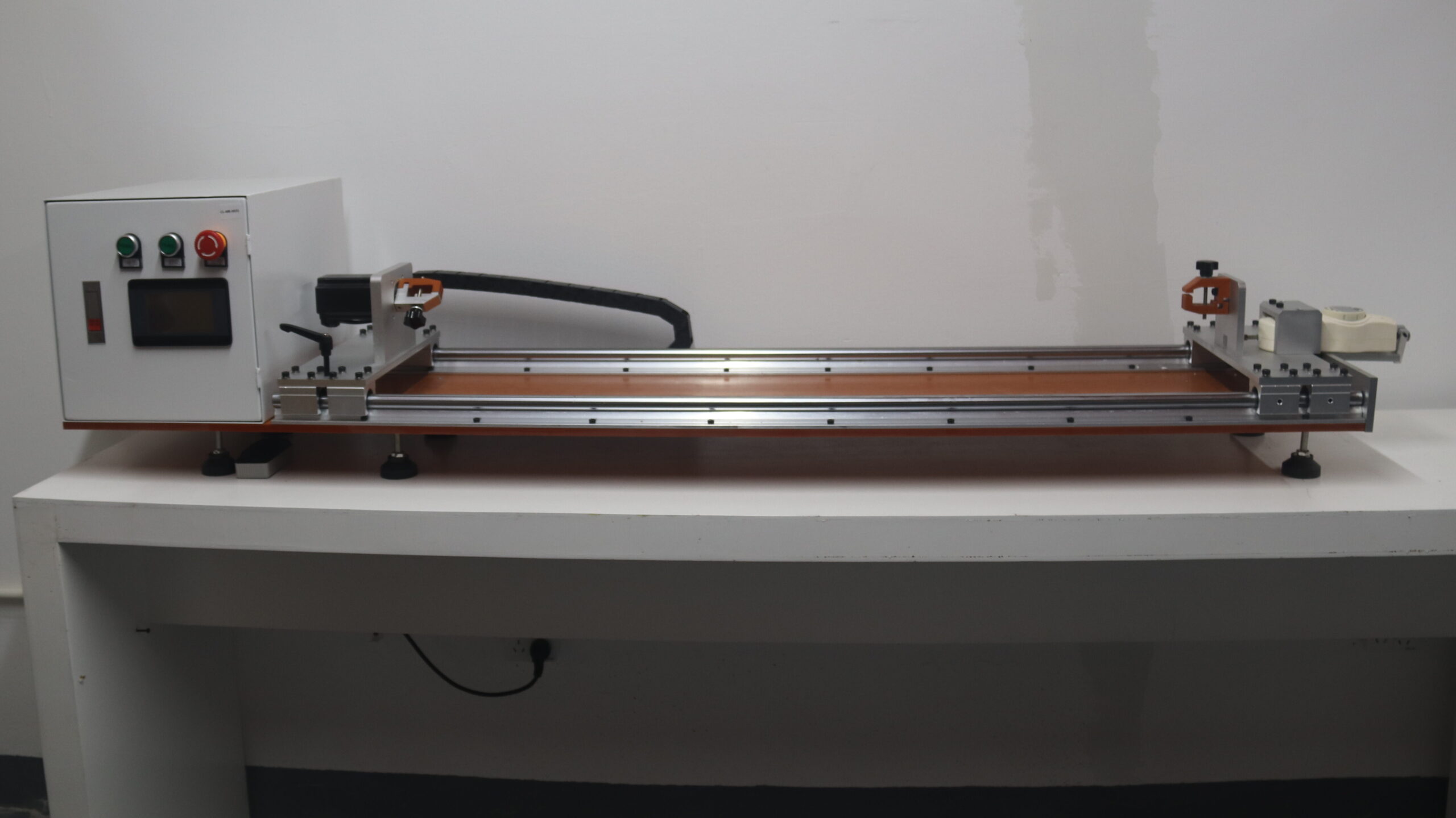

Coordinate with the manufacturer to schedule a visit to their factory facilities. Arrange the visit well in advance to ensure availability and adequate preparation on both sides. - Observe Production Processes:

During the factory visit, observe the various stages of LED strip light production, from raw material handling to final assembly and testing.

Pay attention to factors such as equipment quality, cleanliness, organization, and adherence to safety protocols. - Inspect Quality Control Measures:

Evaluate the manufacturer’s quality control measures and procedures for ensuring product quality and consistency.

Assess the effectiveness of quality inspections, testing protocols, and adherence to industry standards. - Meet the Production Team:

Take the opportunity to meet with key personnel involved in the production process, including engineers, technicians, and quality assurance staff.

Engage in discussions to gain insights into their expertise, experience, and commitment to quality. - Examine Facility Conditions:

Assess the overall condition of the factory facilities, including infrastructure, workspaces, and environmental conditions.

Look for signs of cleanliness, organization, and compliance with health and safety regulations. - Review Certifications and Compliance:

Verify the manufacturer’s certifications and compliance with relevant industry standards and regulations. Look for certifications such as ISO 9001 for quality management and compliance with safety standards such as CE and RoHS. - Discuss Customization Options:

Use the opportunity to discuss customization options and tailor-made solutions to meet your specific requirements.

Clarify your expectations and assess the manufacturer’s ability to accommodate customization requests. - Address Any Concerns:

Raise any concerns or questions you may have during the factory visit and seek clarification from the manufacturer. Addressing issues directly allows for transparent communication and enables both parties to work towards resolving potential challenges. - Evaluate Capacity and Scalability:

Assess the manufacturer’s production capacity, scalability, and flexibility to accommodate your future growth and demand fluctuations.

Ensure that the manufacturer has the capability to meet your volume requirements and delivery timelines. - Build Rapport and Trust:

Use the factory visit as an opportunity to build rapport and establish trust with the manufacturer’s team. Cultivate a positive working relationship based on mutual respect, transparency, and shared objectives.

By visiting the manufacturer’s factory in China, you can gain firsthand knowledge and insights into their operations, quality standards, and capabilities, enabling you to make well-informed decisions and forge a successful partnership for the production of low voltage 3528 LED strip lights.

By meticulously assessing each of these critical factors and conducting exhaustive due diligence, you can effectively identify and select a trustworthy manufacturer of low voltage 3528 LED strip lights in China that precisely matches your unique specifications, quality expectations, and business objectives.

This thorough approach ensures that you establish a reliable partnership with a manufacturer capable of delivering superior products consistently and meeting your long-term needs with excellence and reliability.